Being ISO 9001 and HACCP certified, our production facilities have standard operating procedures in place which guarantee that the material produced meets the specifications and safety norms laid down by our customers.

We have a BMR system (Batch Manufacturing Record) in place by which all the processing parameters, for each batch produced, are recorded and are available for future reference and/or verification. This system goes a long way in ensuring consistency across batches.

Apart from external certification agencies, our facilities are audited annually by top multinational food and pet food customers and we have successfully met their standards every single time.

Our processes and controls include:

- Raw material receipt from pre-approved suppliers

- Documentation of various in-process parameters for repeatability and consistency in the final product

- Water treatment plant for treating water prior to use in the process

- In-process material and finished material passed through magnets at various stages

- Finished material also passed through metal detector

- Glass policy

- Separate areas for raw material storage, processing, packing and finished goods

- Pest Control Programme which covers the inside and outside of the facilities

- Established and reliable Transporters for finished goods transport

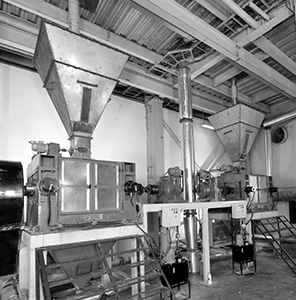

All the latest manufacturing innovations in the field of Guar have been incorporated in the Fast Hydrating Guar plant which was commissioned in 2013.

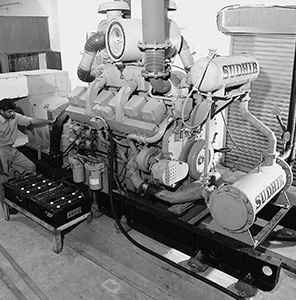

In-house power generation capability at our factories allow for continuous production, so delivery deadlines are met – a Premcem delivery is on time, every time.

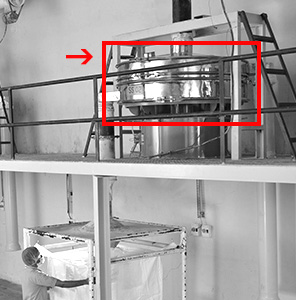

Safety Screen prior to packing, for removal of any foreign matter which may have accidentally gone into the product.